Optimized analog front-end design for edge AI

Key Takeaways:

- AI models see data differently: what makes sense to a digital processor may not be useful to an AI model, so avoid over-filtering and consider separate data paths

- Consider training needs: models trained at the edge will need labeled data (such as clean, noisy, good, faulty)

- Analog data is diverse: match the amplifier to the source, consider the bandwidth needs of the model and the path’s signal-to-noise ratio

Machine learning (ML) and artificial intelligence (AI) have expanded the market for smart, low-power devices. Capturing and interpreting sensor data streams leads to novel applications. ML turns simple sensors into smart leak detectors by inferring why the pressure in a pipe has changed. AI can utilize microphones in audio equipment to detect events within the home, such as break-ins or an occupant falling.

For many applications that rely on real-world data, the analog front-end (AFE) is one of the most important design elements as it functions as a bridge to the digital world. At a high level, AFEs delivering data to a machine-learning back-end have broadly similar design needs to conventional data-acquisition and signal-processing systems.

But in some applications, particularly those in transition from IoT to AIoT, the data is doing double-duty. Sensors could be used for conventional data analysis by back-end systems and also as real-time input to AI models. There are trade-offs implied by this split, but it could also deliver greater freedom in the AFE architecture. Any design freedom must still address overall cost, power efficiency and system reliability.

The importance of bandwidth and signal-to-noise ratio

Accuracy is often an imperative with analog signals. The signal path must deliver the bandwidth and signal-to-noise ratio required by the front-end’s digitizer. When using AI, designers will be more diligent when avoiding distortion, as introducing spurious signals during training could compromise model training.

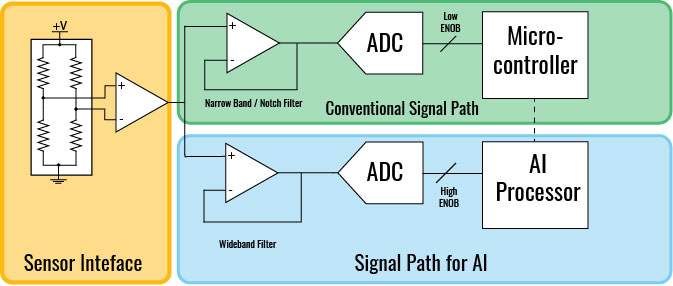

The AFE brings sensor data into the digital domain

The classic AFE may need to change to accommodate the sensor and digital processing sections, and the AI model’s needs which may be different. (Source: Avnet)

For signals with a wide dynamic range, it may make sense to employ automated gain control (AGC) to ensure there is enough detail in the recorded signal under all practical conditions. The changes in amplification should also be passed to the digitizer and synchronized with the sensor data so they can be recorded as features during AI training or combined by a preprocessing step into higher-resolution samples. If not, the model may learn the wrong features during training.

Interfacing AI systems with multi-sensor designs

Multi-sensor designs introduce another consideration. Devices that process biological signals or industrial condition-monitoring systems often need to process multiple types of data together. Time-synchronized data will deliver the best results as changes in group delay caused by filtering or digitization pipelines of different depths can change the relationship between signals.

The use of AI may lead the designer to make choices they might not make for simpler systems. For example, aggressive low- and high-pass filtering might help deliver signals that are easier for traditional software to interpret. But this filtering may obscure signal features that are useful to the AI.

Design Tip – Analog Switches & Multiplexers

Analog switches and multiplexers perform an important role in AFEs where multiple sensors are used in the signal chain. Typically, devices are digitally addressed and controlled, switches selectively connect inputs to outputs, while multiplexers route a specific input to a common output. Design considerations include resistance, switching speed, bandwidth and crosstalk.

Avnet offers nearly 1,800 analog switch or multiplexer variants from 13 different suppliers. Find them here.

For example, high-pass filtering can be useful for removing apparent signal drift but will also remove cues from low-frequency sources, such as long-term changes in pressure. Low-pass filtering may remove high-frequency signal components, such as transients, that are useful for AI-based interpretation. It may be better to perform the filtering digitally after conversion for other downstream uses of the data.

Techniques for optimizing energy efficiency in AFEs

Programmable AFEs, or interchangeable AFE pipelines, can improve energy optimization. It is common for edge devices to operate in a low-energy “always on” mode, acquiring signals at a relatively low level of accuracy while the AI model is inactive. Once a signal passes a threshold, the system wakes the AI accelerator and moves into a high-accuracy acquisition mode.

That change can be accommodated in some cases by programming the preamplifiers and similar components in the AFE to switch between low-power and low-noise modes dynamically.

A different approach often used in biomedical sensors is to use changes in duty cycles to reduce overall energy. In the low-power state, the AFE may operate at a relatively low data rate and powered down during quiet intervals. The risk arises of the system missing important events. An alternative is to use a separate, low-accuracy AFE circuit that runs at nanowatt levels. This circuitry may be quite different to the main AFE signal path.

In audio sensing, one possibility is to use a frequency-detection circuit coupled with a comparator to listen for specific events captured by a microphone. A basic frequency detector, consisting of a simple bandpass filter and comparator, may wake the system or move the low-power AFE into a second, higher-power state, but not the full wakefulness mode that engages the back-end digital AI model.

In this state, a circuit such as a generalized impedance converter can be manipulated to sweep the frequency range and look for further peaks to see if the incoming signal meets the wakeup criteria. That multistage approach will limit the time during which the full AI model needs to be active.

Breaking down analog front-ends for AI

| Feature | Conventional AFE | AI-Optimized AFE |

|---|---|---|

| Primary Role | Bridge sensor signals to digital domain for standard processing | Bridge sensor signals for both conventional analysis and AI inference |

| Bandwidth & SNR | Meets digitizer requirements for accuracy | Higher diligence to avoid distortion; critical for AI training quality |

| Bit Resolution | Typically matches ADC specs (e.g., 8-10 bits) | May require higher ENOB (12–14 bits) even if AI uses 8-bit inference |

| Filtering Approach | Aggressive low/high-pass filtering for clean signals | Minimal filtering pre-conversion to preserve features for AI models |

| Dynamic Range Handling | Basic gain control | Automated Gain Control (AGC) with synchronization for AI feature extraction |

| Multi-Sensor Sync | Basic synchronization | Precise time alignment to avoid group delay issues for multi-modal AI |

| Design Trade-offs | Cost and reliability | Balances cost, power, and AI model accuracy requirements |

Further advances in AI theory enable more sophisticated analog-domain processing before digitization. Some vendors have specialized in neural-network devices that combine on-chip memory with analog computation. Another possibility for AFE-based AI that results in a lower hardware overhead is reservoir computing. This uses concepts from the theory of recurrent neural networks. A signal fed back into a randomly connected network, known as the reservoir, can act as a discriminator used by an output layer that is trained to recognize certain output states as representing an event of interest. This provides the ability to train an AFE on trigger states that are more complex than simple threshold detectors.

Another method for trading off AFE signal quality against AI capability is compressive or compressed sensing. This uses known signal characteristics, such as sparsity, to lower the sample rate and, with it, power. Though this mainly affects the choice of sampling rate in the analog-to-digital converter, the AFE still needs to be designed to accommodate the signal’s full bandwidth. At the same time, the AFE may need to incorporate stronger front-end filtering to block interferers that may fold into the measurement frequency range.

Optimizing AFE/AI trade-offs through experimentation

With so many choices, experimentation will be key to determining the best tradeoffs for the target system. Operating at higher bandwidth and resolution specifications is a good start. Data can be readily filtered and converted to the digital domain at lower resolutions, to see how they affect AI model performance.

The results of those experiments can be used to determine the target AFE’s specifications in terms of gain, filtering, bandwidth and the ENOB needed. Such experiments also provide opportunities to experiment with more novel AFE processing, such as reservoir computing and compressive sensing to gauge how well they might enhance the final system.