Case study: Automotive start-up scales global production with Avnet’s strategic hub solution

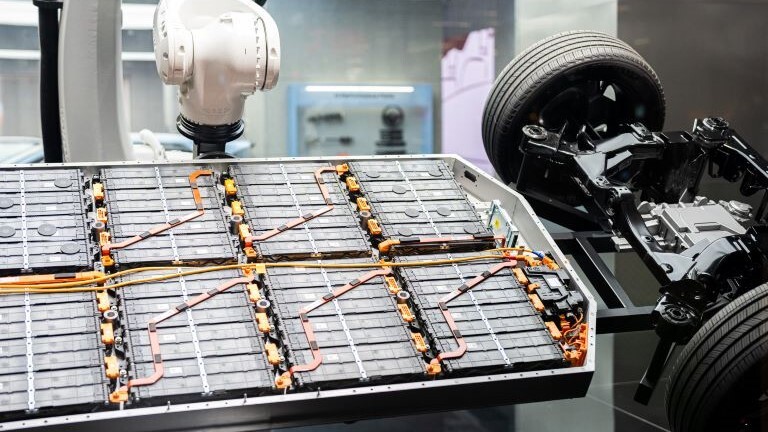

High-growth EV innovator untangles global supply chain complexity

This Americas-based automotive start-up is known for pushing the boundaries of innovation and performance.

As the company scaled production across multiple regions, it faced a familiar challenge: managing a complex, multi-partner global supply chain while maintaining speed, visibility and cost control.

With manufacturing partners in Mexico and Asia, they needed a supply chain solution that could support its “design anywhere, build anywhere” strategy without compromising quality, delivery or financial efficiency.

The Avnet solution: One global partner, total visibility

To address their specific needs, Avnet implemented a comprehensive global hub solution designed to simplify logistics, improve visibility and reduce risk across the supply chain. The solution was built around four key pillars:

-

Global strategic hub model

Avnet established regional inventory hubs, a center for managing physical inventory, in Chandler, Arizona; Guadalajara, Mexico; and Hong Kong to support the start-up’s contract manufacturers (CMs). These hubs enabled just-in-time fulfillment, reduced lead times and ensured consistent execution across regions.

-

Supply assurance and risk mitigation

Avnet’s planning and implementation framework included:

- Monthly forecasts from the customer with a 12-month demand horizon

- Inventory pipelining based on forecast needs

- 90-day financial and physical ownership postponement

- Buffer inventory for upside flexibility

This structure ensured that inventory was available when needed, while minimizing financial exposure and reducing the risk of supply disruption.

-

Real-time visibility and reporting

The customer gained 24/7 access to global supply and commit data via Avnet’s digital tools. Reporting included:

- Global dashboards for inventory, orders, billing and consumption patterns

- Forecast and contract manufacturer backlog reports what is CM?

- Forecast accuracy analysis

- Aged inventory alerts

This transparency empowered the customer to make faster, data-driven decisions and reduced the need for manual escalations.

-

Dedicated program managers

Avnet assigned dedicated supply chain program and sales associates to oversee the engagement. These experts coordinated with the customer’s CMs, managed inventory strategy and ensured alignment with the customer’s evolving goals. Engineering support, including BOM Health Risk Assessments (BHRA) and NPI readiness, was also embedded into the program.

The results: Tangible business benefits

The results of the engagement were immediate and measurable:

- Lower inventory on hand: Strategic hubs and forecast-driven planning reduced excess inventory, freeing up cash flow and strengthening the customer’s balance sheet.

- Reduced operating expense: Streamlined order management and less need for escalations led to lower administrative and logistics costs.

- Improved cash flow: Avnet’s inventory financing and ownership postponement allowed the customer to delay capital outlay while maintaining supply readiness.

- Avoided tariffs and expedited freight: Regional hubs and proactive planning helped the customer avoid costly last-minute shipments and import fees.

The program also improved pricing consistency, protected against counterfeit components and enhanced the customer’s ability to respond to market fluctuations.

Industry Insight: Why this matters now

In 2025, the automotive and electronics industries are navigating a perfect storm of disruption and opportunity:

- AI and EV demand: The rise of AI-enabled vehicles and electrification is straining global component supply.

- Geopolitical instability: Trade route volatility and tariffs are increasing the cost and complexity of global logistics.

- Counterfeit risk: As demand for legacy components grows, so does the risk of counterfeit parts entering the supply chain.

- Customer expectations: EV buyers expect rapid innovation cycles, which puts pressure on supply chains to be more agile and responsive.

Avnet’s global strategic hub model is built to address these realities, offering the flexibility, visibility and control that modern manufacturers need to stay competitive.

Looking ahead? A partnership built for growth

Avnet supports the customer through:

- Strategic business reviews and ongoing alignment with corporate and site goals and objectives

- Enhanced analytics and digital enablement

- Expansion of inventory hubs to support additional regions and product lines

Together, we’re proving that with the right partner, supply chain complexity can become a competitive advantage.

The Avnet advantage

- Time-to-market support

Early involvement from concept to design - Supply assurance

Planning methodology and execution to minimize supply gaps - Our people

Dedicated support teams enable focus on more strategic imperatives - One global partner leverages efficiencies as the business scales