How the IoT will Change the Supply Chain?

Enhance Your Competitive Advantage with IoT

The potential applications of Internet of Things (IoT) technology across any industry or sector are vast. Existing and future IoT applications promise new ways of value creation and revenue streams for businesses in a digital world. For supply chains, IoT technologies allow creation of a broad framework within which rapid evolution in an increasingly complex environment can be visualized and implemented. This evolution is based on the possibility of being able to integrate all relevant information in any value chain, understand the interdependencies amongst those pieces of information almost instantaneously, and leverage advanced analytics to arrive at more optimized decisions.

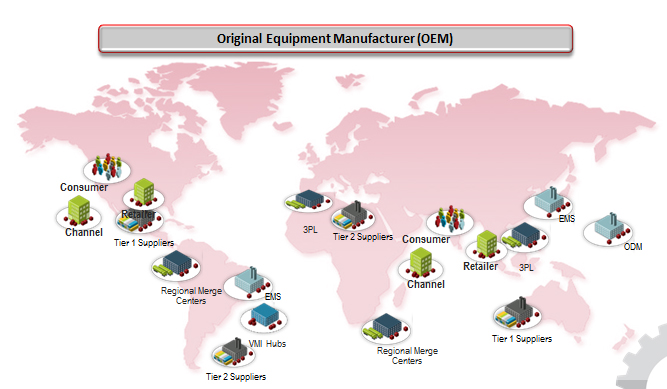

An IoT enabled supply chain can be visualized as an intelligent interconnected network that binds together multiple tiers of suppliers, contract manufacturers, service providers, distributors and customers, physically located across different regions of the world. Information created, processed and interpreted by distributed smart objects and systems in this intelligent network eliminates visibility gaps, and injects enormous flexibility into the network. Supply chain management in such a network would evolve from

-decision support to simulation

-modeling and predictive capabilities in support of optimizing costs

-service level and

-quality in near real-time

Systems and smart objects with embedded intelligence will be able to make certain decisions and adjust automatically to complex situations, with managers focused on optimizing global capabilities through orchestration of the supply chain. Business processes in supply chains that are currently based around static data analysis and data structures will need to evolve so that they can adjust in near real-time in pursuit of new value creation. IoT’s ability to monitor continuously, sense constraints and respond almost instantaneously under guidance of an autonomous system or an intelligent network, will create significant opportunities for cross-enterprise process optimization and innovation. In turn, this would concurrently drive cost containment, as well as improve time to market.

Decision making capability of smart machines in an IoT enabled supply chain would also impact the supply chain organization structure. Conventional supply chain tasks in planning, procurement, supplier management and logistics would be better addressed by data driven intelligent systems in a collaborative cross-enterprise environment. Skill sets for supply chain professionals will need to go through a transformation, and their primary role would focus on designing inter-enterprise collaboration, network and capability optimization, risk and disruption management, and supply chain orchestration in order to create differentiation and competitive advantages.

"In a global supply chain, deployment of IoT technologies can improve customer service, revenue growth, profitability, working capital deployment, asset utilization, time to market, waste reduction, sustainability, equipment/product uptime, security, agility and risk mitigation."

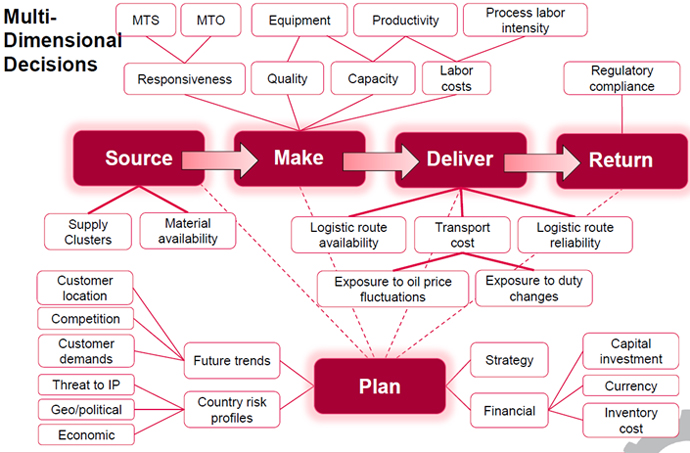

The first schematic shows a typical high-tech OEM’s value chain with a multi-region supply network, global manufacturing sites, multi-region distribution network, along with third party service providers and a global customer base. The second schematic shows some of the dimensions that need to be factored into decision making in global supply chain processes. IoT-enabled supply chains will cede decision making on some of these dimensions to smart objects and systems. The following paragraphs provide a glimpse into some of the benefits that would accrue due to distributed and near real time sensing and decision making.

Original Equipment Manufacturer (OEM)

Ability to track products (raw material or finished) and associated attributes like type, count and geo data using IoT technologies through their entire life cycle journey from a tier-n supplier to the end customer will impact sourcing strategies, inventory management and logistics costs. As an example, inability of a supplier to deliver on time could lead the connected intelligent system to launch an automatic search for the product in the distributed raw material inventory pool, or could result in a procurement trigger to an alternate supplier. This would ensure that there is no negative impact on production schedules, revenue streams and customer service. Consider another example where production constraints at a proprietary product supplier delays raw material delivery by 2 days. The intelligent system would sense the impending delay and readjust the material delivery dates for other suppliers. In turn, these suppliers would possibly be able to route this material to other customers, thus optimizing working capital and revenue stream for the network. The production sites would receive automatic guidance related to delay in raw material delivery and would be able to optimize the machine and production schedules. Fixed asset and raw material utilization would thus improve as asset availability and asset demand would get matched. Supply network risk management would improve as supply status would be monitored continuously, and constraints would be addressed in real time.

Multi-Dimensional Decisions diagram

Ability to sense finished product demand through embedded intelligent objects will enable the networked system to try and match it with available finished inventory distributed across warehouses, and possibly reassign the inventory to the sales channel that has immediate demand. When no inventory is available systems will be able to check manufacturing capacity and raw material availability, and automatically send a production trigger to the relevant site. Continuous matching of demand against availability will positively impact revenue, profitability and customer service, while simultaneously optimizing finished inventory. Significant benefits would accrue to the maintenance and spare parts supply chain too. Real time monitoring of equipment at the customer site would drive predictive maintenance techniques, leading to minimization of equipment downtime.

As technology and standards evolve, IoT presents a real opportunity towards enhancing competitive advantage through linking sensors, actuators, systems, embedded intelligence, advanced analytics and people. The business opportunities are significant. Supply chains that leverage these capabilities will differentiate themselves from those that do not.