Understanding the Power of Battery Management Systems

According to the International Energy Agency (IEA), the number of electric vehicles (EV) reached 2 million globally in 2016. The EV market is furthermore slated to grow exponentially to 9-20 million by 2020 and to 40-90 million by 2025.

Equally astonishing, however, are the EV safety incidents we see from time to time in news reports. An analysis of all 49 cases of EV incidents that have occurred in China since 2010 shows that as much as 50% were due to battery malfunction. This is unsurprising given that battery packs, the “heart” of EVs, are made up of thousands of monolithic lithium batteries. Among all commercially viable battery technologies, lithium batteries currently exhibit the highest energy density though they are naturally volatile and could potentially explode in the event of overcharge, overtemperature, overdischarge and other operating issues, or if there are issues in manufacturing techniques and structural materials.This is where BMS (battery management system)—a solution that enables lithium batteries to power EVs while controlling their volatile nature—steps in.

BMS is a new technology that progressed alongside advancements in EV development. As safety requirements for automobiles are particular stringent, people have naturally developed high expectations for the functionality of BMSs. For example, the ideal BMS must be capable of preventing overcharge/overdischarge, regulating temperature, maintaining battery voltage and temperature equilibrium, predicting remaining battery capacity and remaining mileage etc. They must also be capable of real-time monitoring and adjusting battery management parameters while working in conjunction with other parallel subsystems. In short, BMSs are monitoring systems that must be able to monitor, analyze, control and provide feedback on power batteries to ensure efficiency and operational safety.

- Accurate prediction of battery status. This pertains to accurate measurement and prediction of parameters for battery SOC (State of Charge), SOP (State of Power) and SOH (State of Health), conducting dynamic monitoring and providing diagnosis for each battery, and building historical files on battery use, thereby providing a basis for data analysis and control decisions.

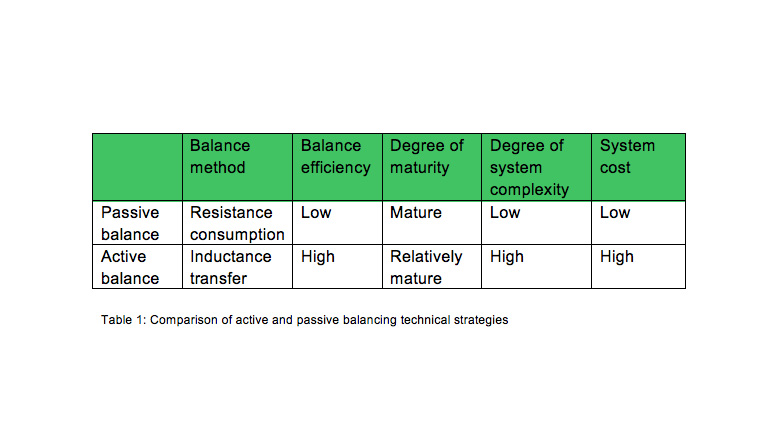

- Energy balance. Performance discrepancies between different batteries within a battery pack can negatively affect lifespan and system usage. These discrepancies must be mitigated through energy balancing measures to ensure conformity among different batteries and perform dynamic "maintenance" on the battery pack. BMS currently utilize active balance and passive balance strategies each of which offer unique advantages (see Table 1).

- Protection. BMSs are able to protect the battery pack and respond rapidly in the event of malfunction due to overcharge, overdischarge, overcurrent, or over/undertemperature.

- Data communication. Data communication mechanisms can be established using CAN BUS or other methods to transmit data to the display system, vehicle control system, charging system and other external equipment. Some BMSs are even equipped with Wi-Fi transmission capability for cloud connection.

To support the above BMS functions, technology providers have been actively developing new products and solutions. For example, the Maxim Integrated MAX14920/MAX14921 battery measurement analog front-end devices can support high precision sampling of voltage and provide level shifting for primary/secondary battery packs up to 16 cells/+65V (max) and support passive balancing through an external FET driver.

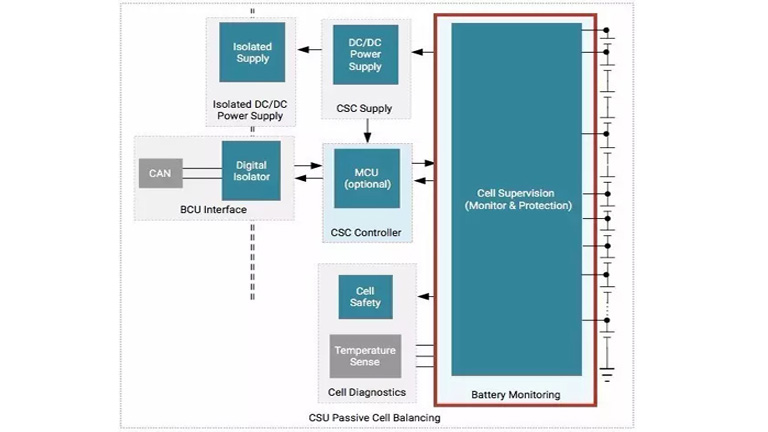

While Maxim Integrated offers high performance "products", Texas Instruments (TI) provides full "solutions". TI's bq76PL455A-Q1 is an integrated 16-cell battery monitoring and protection device based on which a comprehensive passive balance battery solution can be built. It can be used to monitor and detect various malfunctions such as overvoltage, undervoltage, overtemperature and communication faults, and allows up to sixteen bq76PL455A-Q1 devices to communicate with a host via a single high-speed Universal Asynchronous Receiver/Transmitter (UART) interface.

Diagram 1: TI passive balance battery solution

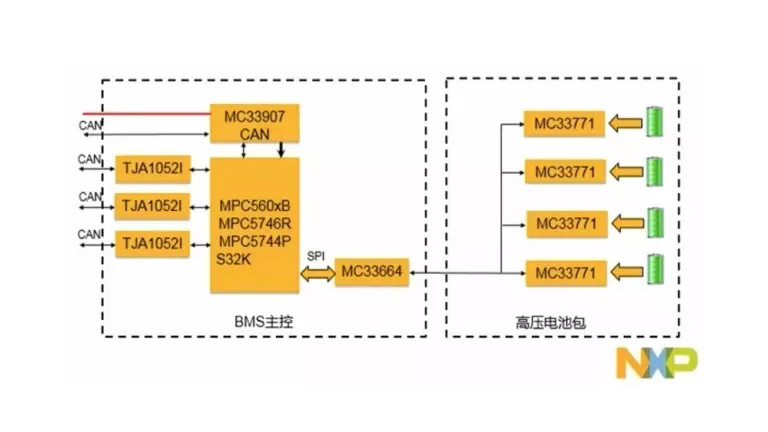

NXP, on the other hand, leverages its comprehensive automobile electronic product lines to provide a comprehensive BMS solution that encompasses micro controllers MCUs, analog front-end battery controller ICs, isolated network high speed transceivers, system base chips (SBC) and others functions. Customers that utilize the solution can manage high voltages of 800V and above.

Diagram 2: NXP integrated BMS solution

Aside from the above mentioned hardware capabilities, BMS system designs require corresponding software capabilities, i.e. the development of a core algorithm. A high quality algorithm enhances battery status prediction accuracy and offers strong correction capabilities, thereby mitigating the impact of hardware issues such as battery quality. This allows precise control even for batteries with a lesser degree of uniformity, hence reducing overall system cost. The advantages and pitfalls of an algorithm is also reflected in the hardware resources required. High performance algorithms require only a low amount of CPU computing resources, greatly enhancing system efficiency.

According to estimates, China's EV battery market will reach RMB 120 billion by 2010, at which time the EV BMS market is expected to be valued at RMB 17 billion. Although the cost of BMS relative to the entire EV is relatively low, developers should nevertheless ensure it is tightly integrated into EV design to ensure that power batteries don’t become ticking bombs.