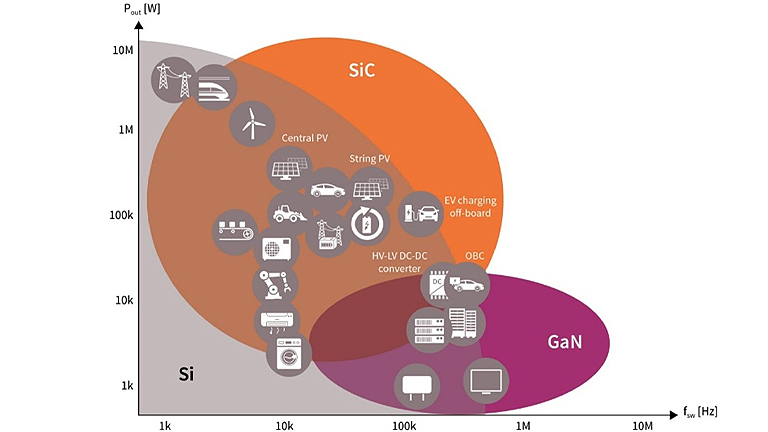

As technology continues to progress, the demand for improved capabilities in power device design grows. The next essential step is to identify which of these new WBG power electronics materials best suit your design needs.

How to pick the right technology for your designs?

The secret of your success lies in the power of choice. Transitioning from conventional semiconductors to wide bandgap (WBG) semiconductors enables enhanced power efficiency, reduced size, lighter weight, and potentially lower overall costs for your applications. The next crucial leap toward an energy-efficient world hinges on the adoption of these novel materials.

With that, materials such as Gallium Nitride (GaN) and Silicon Carbide (SiC) are growing to be the ideal choice for next-generation power converter switches. They both come with unique characteristics, offering different benefits to provide the highest level of system performance in your applications.

|

|

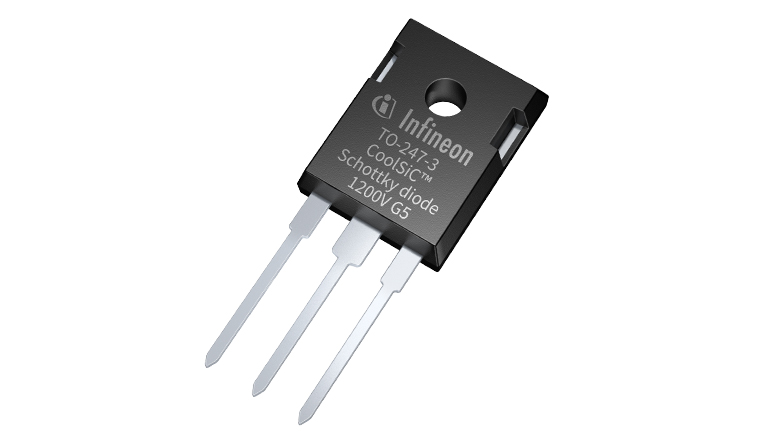

Infineon’s CoolSiC™ Technology |

Infineon’s CoolGaN™ Technology |

|

Benefits |

|

|

Understanding their differences

Electron mobility: GaN has a higher electron mobility than SiC

Electron mobility plays a pivotal role in determining a WBG semiconductor’s suitability for high-frequency and fast-switching applications. With a higher electron mobility, GaN can switch faster and operate at faster frequencies. This is advantageous in applications that require rapid and precise switching of electrical signals such as wireless communication and radio frequency (RF) amplifiers. This characteristic also enables GaN the potential for miniaturization of electronic systems, leading to lighter and more compact designs.

Breakdown voltage: SiC has a higher breakdown voltage than GaN

The breakdown voltage of a semiconductor material is a critical parameter that determines its suitability for high-voltage applications. This makes SiC better suited for high-voltage applications such as motor drives used in industrial, automotive, and renewable energy applications.

Thermal Conductivity: SiC has a higher thermal conductivity than GaN

To determine a material’s suitability in its performance for high-power applications, especially those in relation to heat dissipation and thermal management, we need to look at its thermal conductivity. The combination of crystal structure and bonding characteristics in SiC, makes SiC particularly well-suited for applications where efficient heat management is crucial.

Integration: GaN can be integrated with other materials like silicon, whereas SiC requires a more specialized manufacturing process.

GaN’s integration flexibility offers opportunities for system-level integration and development of hybrid semiconductor solutions whereas SiC requires careful considerations before integration with other materials.

Conclusion

When selecting between SiC and GaN for specific applications, designers and engineers need to consider trade-offs between breakdown voltage, switching speed, and other performance characteristics based on their application's requirements.

Product selection guide

High-voltage switches 500 V - 950 V CoolMOS™ - CoolSiC™ - CoolGaN™

CoolSiC™

Infineon's CoolSiC™ solutions are based on proven, high-quality volume manufacturing, ensuring benchmark reliability for customers. With a wide bandgap of 3 electronvolts (eV), it is suitable for high breakdown and power applications that operate at high frequencies.

CoolGaN™

Infineon’s GaN transistors are highly efficient for power conversion in the voltage range of up to 700 V. With a wider bandgap of 3.4 electronvolts, GaN has ten times higher breakdown field and double the electron mobility compared to silicon. The output charge and gate charge are ten times lower than with silicon, and the reverse recovery charge is almost zero, making it ideal for high frequency operations.

GaN-based power devices are preferred

in modern resonant topologies and enable new approaches